5 great case projects for electronic components

How can electronic components be sold when they are often only a tiny part in a large unit? Manufacturers of sensors, cables, drive and control technology or other electronic components are faced with this and other problems.

Discover more in our best practice examples:

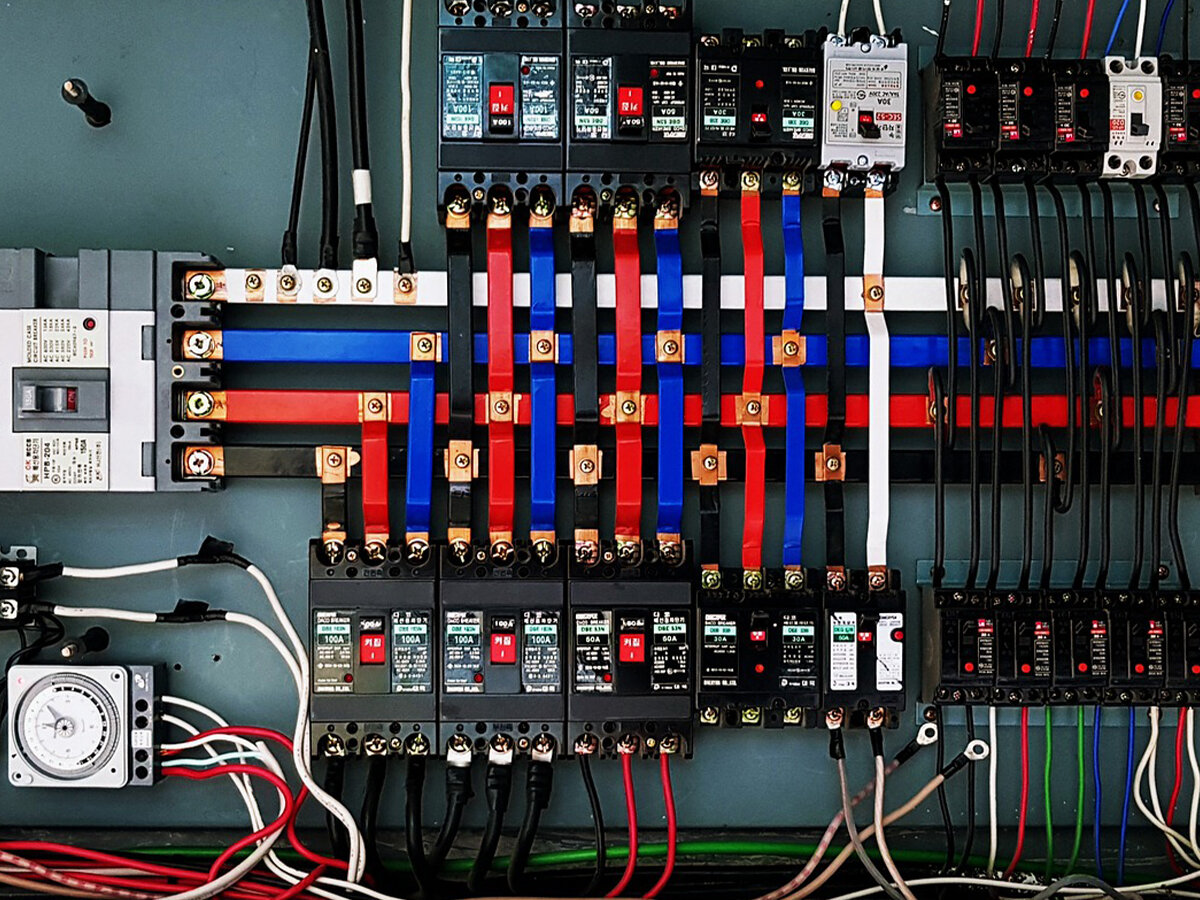

#1 Demo case for sensors

Customer requirement:

Our customer has developed a flow sensor with leakage detection that detects even the smallest holes with little effort. But how can the sales department demonstrate the functionality of the sensor to the customer if there is no machine available?

Solution from bwh:

Together with our customer, a demo case was developed that contains all the necessary components for a live test. A WLAN router, a fan, various other electrical parts and a complete power supply for the devices find space in the case. The only visible part is the cold appliance plug on the outside. Parts that are not needed are stowed under a panel and the rest can be easily operated by the field staff. The prospective customer even has the opportunity to test the sensor himself. This creates real customer experiences and the product presentation is guaranteed to be remembered.

We have many more customer examples from this area. Feel free to take a look at other cases for sensor technology.

#1 Demo cases for sensors

Customer requirement:

Our customer has developed a flow sensor with leakage detection that detects even the smallest holes with little effort. But how can the sales department demonstrate the functionality of the sensor to the customer if there is no machine available?

Solution from bwh:

Together with our customer, a demo case was developed that contains all the necessary components for a live test. A WLAN router, a fan, various other electrical parts and a complete power supply for the devices find space in the case. The only visible part is the cold appliance plug on the outside. Parts that are not needed are stowed under a panel and the rest can be easily operated by the field staff. The prospective customer even has the opportunity to test the sensor himself. This creates real customer experiences and the product presentation is guaranteed to be remembered.

We have many more customer examples from this area. Feel free to take a look at other cases for sensor technology.

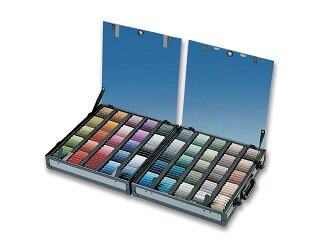

#2 Transport box for trainings

Customer requirement:

Only through good staff training can a company ensure that its products are used or sold optimally. Our customer has subsidiaries all over the world and wants to supply all of them equally with training equipment. But how can the small, sensitive parts be transported or stored on site in the best possible way?

Solution from bwh:

After a detailed consultation, our customer decided on the Casys Box transport box. It is very robust, can therefore withstand a lot during transport and is airworthy. An additional plus point: the box can be easily customised. The coloured impact protection strip is available in several colours or can be ordered in colours of your choice. Our customer therefore chose his company colour yellow.

To make optimal use of the inside of the box, several foam trays are stacked on top of each other. A separate cut-out in the foam was individually cut for each single training component. This means that each component has its own fixed place. Nothing can slip and is stored well and safely in the box even after use.

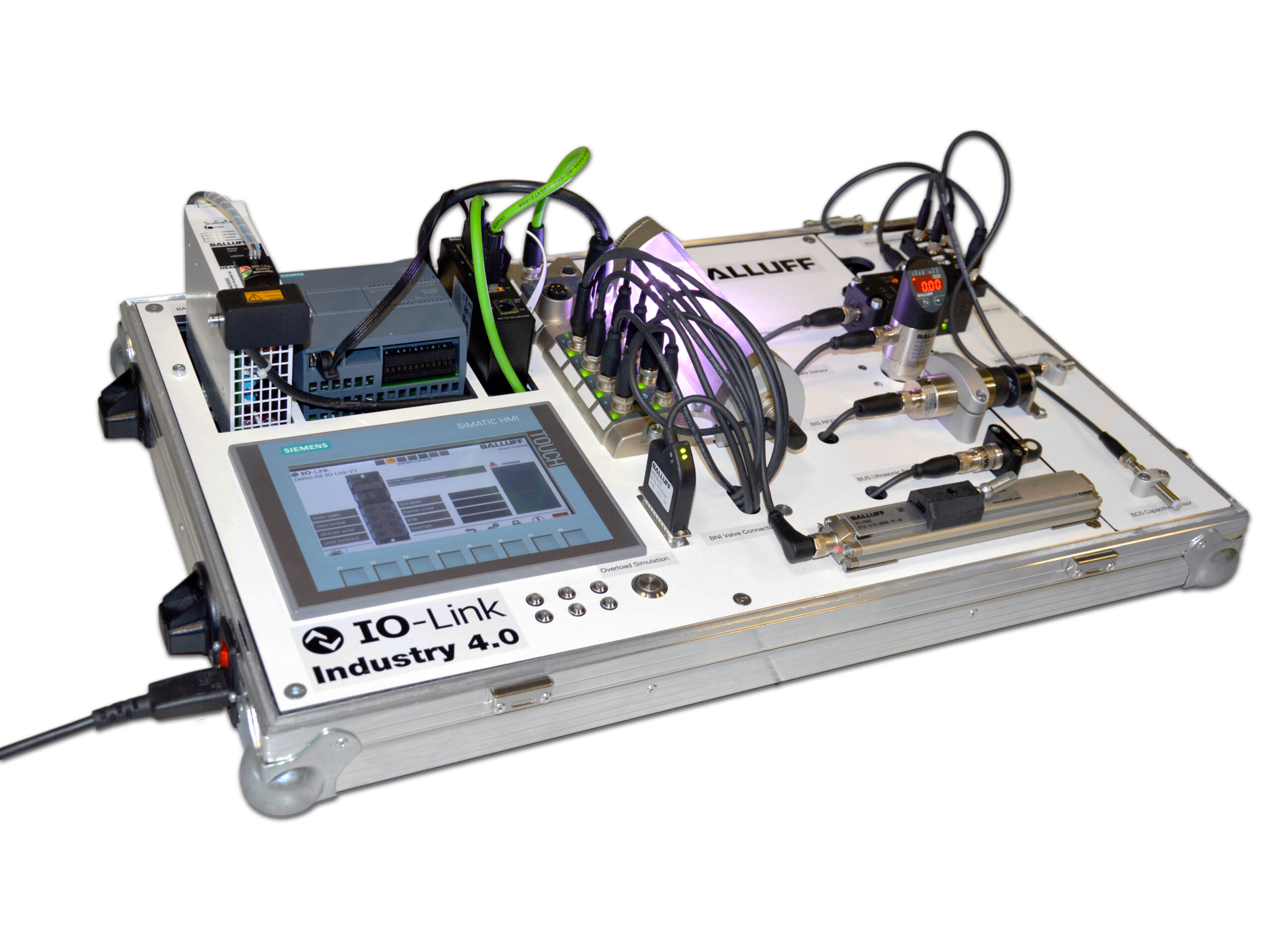

#3 Sample machine in a case

Customer requirement:

Our customer wants to present its sensors and automation components in the best possible way in sales. To explain this only theoretically is difficult. Because normally, his products provide real-time status messages from machines and systems. Nice words are not enough for this – actions have to convince. But how much high-tech fits into a case? For a live test, a whole lot of equipment has to travel.

Solution from bwh:

A sample machine was specially developed for this, which was mounted on a plate. Thanks to the flexibility of the aluminium cases, we were able to customise a case exactly to these dimensions. The plate fits in perfectly. All the machine’s cabling disappears inside and all the parts needed for the test are right at hand. All you have to do is remove the lid and connect the plug to the socket. Everything is ready to start.

Equipped with wheels and a telescopic handle, the case can be transported easily despite its heavy weight. In addition, the outer shell serves as a perfect advertising platform. With individual imprinting, it is immediately recognisable who the case belongs to.

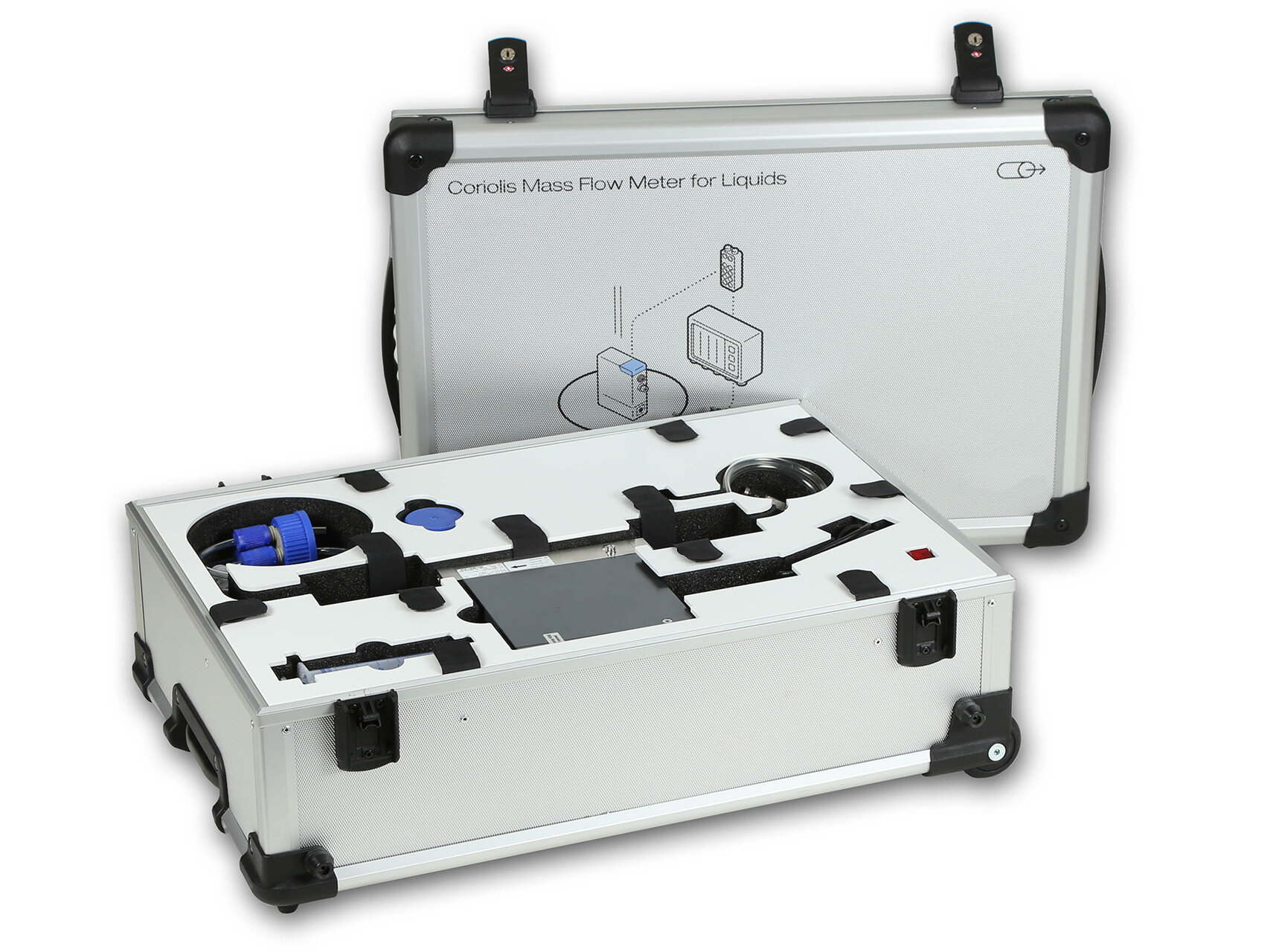

#3 Sample machine in a case

Customer requirement:

Our customer wants to present its sensors and automation components in the best possible way in sales. To explain this only theoretically is difficult. Because normally, his products provide real-time status messages from machines and systems. Nice words are not enough for this – actions have to convince. But how much high-tech fits into a case? For a live test, a whole lot of equipment has to travel.

Solution from bwh:

A sample machine was specially developed for this, which was mounted on a plate. Thanks to the flexibility of the aluminium cases, we were able to customise a case exactly to these dimensions. The plate fits in perfectly. All the machine’s cabling disappears inside and all the parts needed for the test are right at hand. All you have to do is remove the lid and connect the plug to the socket. Everything is ready to start.

Equipped with wheels and a telescopic handle, the case can be transported easily despite its heavy weight. In addition, the outer shell serves as a perfect advertising platform. With individual imprinting, it is immediately recognisable who the case belongs to.

#4 Presentation case for automation technology

Customer requirement:

presentation case should not only serve the company’s own field staff, but also sales partners and distributors. It must therefore be representative, intuitive to use and survive countless kilometres on the many journeys.

Solution from bwh:

The aluminium frame case type AZKR was tailored exactly to the customer’s wishes. Even at first glance, the digital print on the front of the case catches the eye. A close-up shows the product in detail and already provides initial sales information. In the second step, a foam material was specially cut to fit the products and glued inside the case. Each item now has its fixed place and cannot be damaged during transport.

DThe special highlight: Our customer has already ordered several cases of the same design from us for their various product ranges. All of them are perfectly coordinated with each other. An all-round successful appearance is assured.

#5 Case with own water circuit

Customer requirement:

As a manufacturer of sensor technology, you are not the only one on the market. How can you therefore differentiate yourself from your competitors? This was exactly the problem our customer faced. He has many ideas for a great product promotion. But how can the equipment be transported and then presented in an uncomplicated way at the destination?

Solution from bwh:

A water circuit has been built into a case. Together with the sales representative, the prospective customer can test the sensor live. With the help of a syringe, he determines the water pressure in the circuit himself and evaluates it electronically later. The necessary sensor and the other required technology are completely integrated in the case. The product presentation for the sales representative is thus simple and effective – but with a WOW effect.

#5 Case with own water circuit

Customer requirement:

As a manufacturer of sensor technology, you are not the only one on the market. How can you therefore differentiate yourself from your competitors? This was exactly the problem our customer faced. He has many ideas for a great product promotion. But how can the equipment be transported and then presented in an uncomplicated way at the destination?

Solution from bwh:

A water circuit has been built into a case. Together with the sales representative, the prospective customer can test the sensor live. With the help of a syringe, he determines the water pressure in the circuit himself and evaluates it electronically later. The necessary sensor and the other required technology are completely integrated in the case. The product presentation for the sales representative is thus simple and effective – but with a WOW effect.