Long, wide, flat or curved? Everything is possible in custom case construction

We produce customised cases – for every product. In our current best practice example, we present a transport case for an acoustic camera:

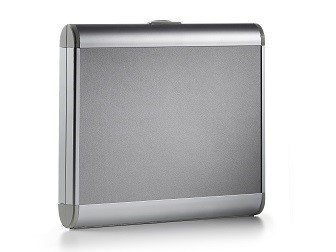

“The unusual shape immediately shows that our case is not a standard one. The material and the shape make it a high-quality case. At the same time, it also underlines our high-tech product, for whose special dimensions the case was developed,” summarises our client’s marketing expert about the new custom case for the measurement equipment for sound visualisation. “In addition, the case is branded with our logo. This creates a high recognition value for our brand.”

Unusual in shape, stable and yet light and manoeuvrable:

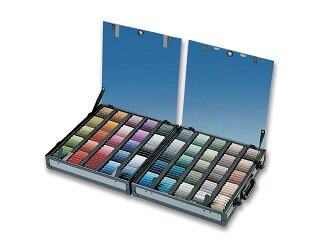

After a detailed briefing, a case was created that can store all the individual components of the acoustic camera, such as sensors, laser distance meter, mobile phone, chargers, tripod and much more, with pinpoint accuracy. No space was wasted and the case is now as big as necessary and as small as possible. Thanks to wheels and a trolley handle, it is easy and safe to transport. Compared to the flight case used previously, the new case for the measuring instruments is much lighter and far more visually appealing. “This would not have been possible with a standard case. After their first experiences with the handling of the case, our customers particularly appreciate the stability and the certainty that everything is safely stowed away. We have only received positive feedback so far.”

Very diverse requirements for transport cases for measurement technology

Whatever the purpose, sensitive technology always needs protection from damage and destruction during transport and daily use. Whether for measurement technology cases or cases for other industries – we treat each project individually. Depending on the nature of the product and the customer’s requirements, we have different materials at our disposal: high-quality solid aluminium, aluminium frame constructions or model variants made of hard-wearing plastics. The requirements are very diverse due to their individuality: they must be robust and handy, but also light, easy to operate and optimal to move. Not only the external protection is important for the life span of the instruments, but also an individually developed case interior that exactly reflects the shape and dimensions of the products.

Conclusion

You have products for which no standard case is an option? Then we are the right partner for you. Based on your requirements, we will develop a custom case for you – not too big and not too small.