Tested quality

Nothing is left to chance in the planning and production of the bwh special cases.

Tested for use under the toughest conditions

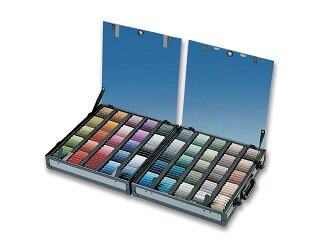

Every detail is selected according to the highest quality standards and must be ideally suited to the intended use. Numerous certificates guarantee this suitability by means of correspondingly tough tests, such as the compatibility tests for the Casys Boxes with extreme temperature fluctuations, humidity or, for example, the special shock resistance required by the US military standard MIL-STD-810. These and other requirements are the benchmark for the development of bwh products: Because wherever bwh cases are used, you can rely on them.

Here is an overview of acquired test certificates for bwh products:

ATA – Airworthiness tests without objections

According to the American ATA flight standard of the “Air Transport Association” the CasysBoxes as well as the SkyBox were certified as airworthy without complaints.

The ATA standard ensures that practically all passenger and cargo aircraft worldwide are uniformly certified according to certain regulations. This enables logistics personnel to work in a uniform and safe manner. The ATA certification according to Spec 300 CAT 1, as it is called, is the standard for all transport containers or cases in the aircraft industry and regulates the requirements for design, development and handling for effective freight logistics.

To ensure that the bwh special cases are also equipped for these standards, the Casys Boxes as well as the Sky Box were subjected to the requirements of the ATA directive according to strict regulations. The suitability for flight was granted for both case systems without any complaints. The extensive tests by the renowned American test laboratory Cascade TEK included drop tests, vibration and impact tests under the toughest conditions.

MIL-STD810G – Suitable for military use

Military applications require special demands on quality and resistance of the products used. The US Armed Forces have summarised the conditions for use in an emergency in a separate, very strict technical standard, MIL-STD810G.

Even though the Casys boxes were not originally developed for military use, they offer all the necessary features required by the American military standard MIL-STD810G. These tests, which specify the environmental test conditions for military equipment, confront the products with extreme temperature fluctuations, different air pressures, the effects of strong sunlight, humidity, contact with chemicals and equally strong vibration and acceleration forces.

IP 54 – Protected against dust and splash water

Functional reliability guaranteed

To ensure that Casys boxes continue to function safely and reliably for many years, they have been designed to meet the requirements of various protection classes. TÜV Rheinland’s IP 54 degree of protection stands for adequate protection against dust loads in harmful quantities and splash water that could penetrate from all sides. IP is the abbreviation for “International Protection” or also “Ingress Protection” – i.e. protection against unintentional ingress of foreign bodies. The test therefore does not require the boxes to be completely dust-tight. However, the safety and functionality of the materials transported in the boxes must not be affected.

IP 67 – Protected against dust and temporary immersion

Functional reliability under difficult conditions

TÜV Rheinland’s IP 67 protection class places particularly high demands on protection against dust. IP is the abbreviation for “International Protection” or “Ingress Protection” – i.e. protection against the unintentional ingress of foreign bodies. IP 67 has a clear definition and stipulates that no dust may penetrate the enclosure to be tested. Also in terms of watertightness, this IP code goes much further than IP 54: For testing, the case – in this example the Casys Box from bwh – is completely submerged under water for half an hour and at a depth of one metre. Only enough water may penetrate to ensure the safety of the transported goods in the Casys Box. The bwh-Casys Box has successfully passed these tests.

ISO 9001 – to ensure quality standards

Everything that serves the quality and optimisation of operational procedures and processes is always in the interest of customer satisfaction.

Successful business management

The successful management of a company requires that all decisions and processes are strategically planned and implemented. In order to avoid having to rethink and decide each individual process again and again, quality management systems (QM system) provide a clear structure for strategic action concepts. Points such as customer orientation or management responsibility and continuous improvement are at the top of the list of the most important principles of a promising QM system. These globally recognised quality management guidelines, which are described in the European standard EN ISO 9001, lead to increased customer orientation and the continuous improvement of all management processes. Regular certification and regular audits of the system introduced individually in each company guarantee its effectiveness. bwh Koffer is one of the first special cases manufacturers to be certified according to EN ISO 9001 since 1995.