When much more than standard solutions are required:

For us, the customer’s product is always the starting point for an individual case! Would you like to find out more about how an individual case is created? Discover our best practice example for the medical industry here:

The problem of the customer:

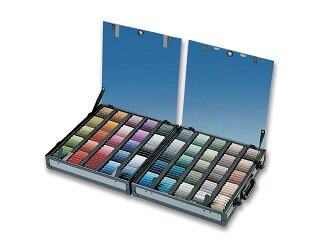

Does the product have to adapt to the case or vice versa? This was precisely the problem facing our customer, a market leader in pharmaceuticals and medical supplies with more than 64,000 employees worldwide. In order to be able to present the latest generation of infusion pumps to the responsible persons in clinics and practices, a presentation case had to be developed that had to be convincing in terms of handling and of course also in terms of design. It is impossible to find something like this as a standard on the market. An own development was therefore inevitable. With clear ideas about the appearance and functionality of the case, those who are responsible quickly came to approached us, as we have been able to establish ourselves as a competent and innovative development partner for years, especially in the field of medical technology. After all, the case had to be something very unique.

The solution of bwh:

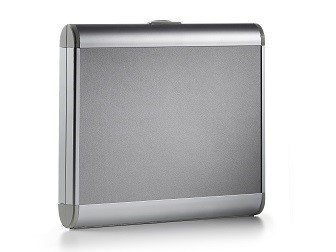

“Robust for transport and yet slim and elegant for presentation to the customer” is how the senior product manager for infusion pumps describes the requirements for the new presentation case to be developed. At the beginning, a joint case layout was developed with the customer’s design agency. The decision was quickly made in favour of an individual shell case, which was to be produced using the thermoforming process. This process allows for a very wide range of design possibilities. bwh Spezialkoffer in particular can refer to many years of experience in this field.

In the meantime, details were clarified in further discussions, for example to ensure the necessary stability of the inlay or to achieve the desired translucent look of the case lid. Many material tests were carried out until the “frosted”, slightly translucent look was achieved. Only after detailed prototyping and subsequent tool construction did the production start with the result of a one hundred percent implementation of the specific customer wishes.

That’s what our customer says:

“For our infusion pumps, we needed an adequate design that would present the devices to the customer in a high-quality manner. The visual appearance had to fit into the corporate design, which was also very important to us, along with all the other requirements, and bwh Spezialkoffer succeeded very well,” says the product manager, describing the joint development work. The implementation was flexible and uncomplicated, and the direct contact with the developers was very helpful, she emphasises. In the meantime, the case is used worldwide for presentations of the pumps and is highly appreciated by the sales staff for its well thought-out handling and elegant design.

Conclusion

As you can see, no requirement is too unusual for us. Do you have very specific ideas about your case? Let’s talk about it. Together with you, we will develop your very own personal design. Just tell us your requirements and we will do the rest.

Would you like to get to know more case projects? On our medical technology page you will find many best practice examples.